Home > Rolls

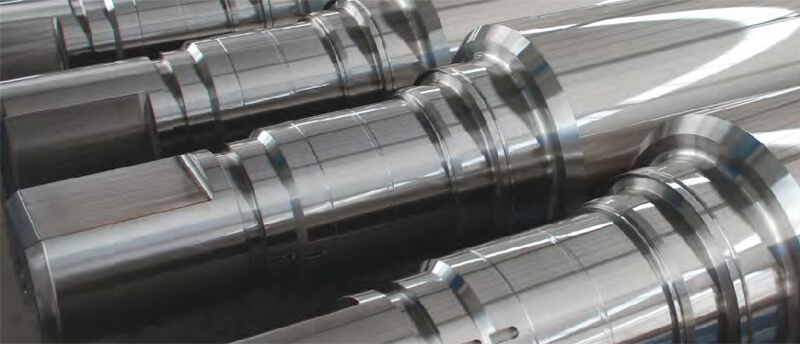

Forged steel work roll performs as a tool to transform materials under normal room temperature. It is the most wear-and-tear spare part during the rolling process. With 2%Cr, 3%Cr, 5%Cr material series, we have greatly improved our products both in terms of both quality and diversification.

The microstructure of HSS roll shows fine and diffuse carbide of MC and M6C embedded in the Martensite. The performance of wear resistance, thermal hardness and thermal fatigue resistance of HSS roll is excellent

Cemented carbide roll is a kind of tool material which consists of tungsten carbide and cobalt with high hardness and wear resistance .To take advantage of high wear resistance,long life and high efficiency of cemented carbide roll rings during the high speed rolling, attention should be paid as follows when purchasing and using cemented carbide roll rings.

The products of HSM have excellent cold forming and deep drawing properties as well as excellent weldability. The products are widely used in boilers, pressure vessels, shipbuilding, etc.

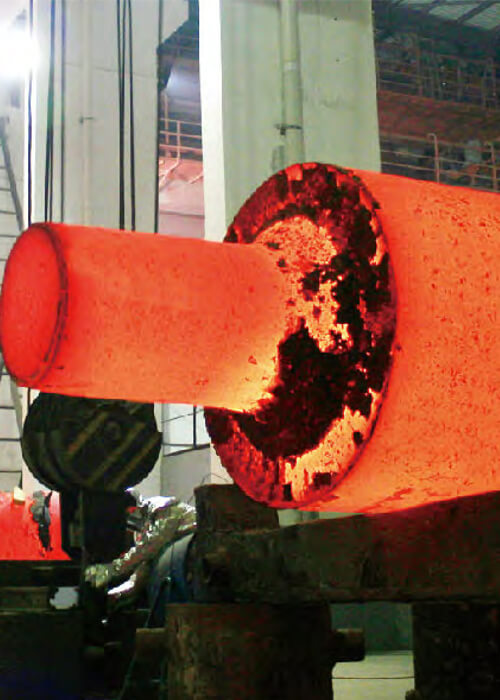

Roll manufacturing requires various technologies, which include metallurgical techniques, heat treatment techniques, machining techniques and testing techniques.By years of development, we are capable of producing a wide range of rolls We can produce rolls by static casting and centrifugal casting, depending on the request of customers In order to control the core process of manufacturing, we imported 2 induction melting furnaces from INDUCTOTHERM Quality is always our core competitiveness