Composite cemented carbide roll rings for hot rolling rods and ribbed steel bars

Installed on the front stands of machines for rolling ribbed steel bars and rods. Composite roll rings can substantially reduce the times of groove changes and roll changes, reduce labor intensity, increase productivity, improve surface quality and yield of rolled material, thus achieving outstanding economic benefits.

- Special cemented carbide grades are used for hot rolling rods and ribbed steel bars.

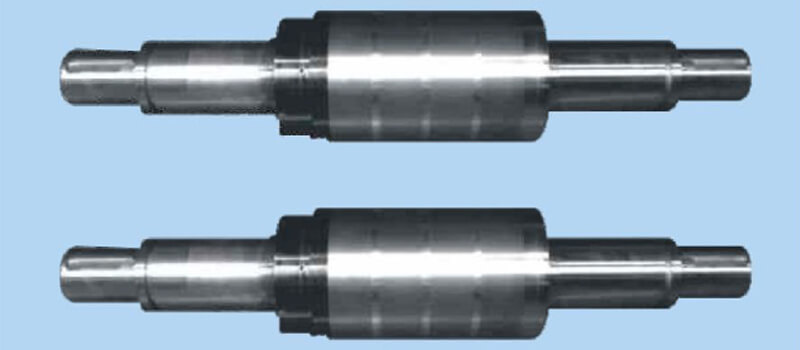

- With hydraulic nuts locking devices and in-feed of oil with pressure of 100-200 Mpa, the hydraulic nuts create an axial pretighening force of 500-1500KN and fasten the cemented carbide roll rings to the mother shafts. The devices are practical in use and reliable and they can insure higher performaces of composite cemented carbide roll rings under the protection of a proper prestress.

- Various cemented carbide roll rings are available with diameter of Φ300-400mm and thickness of 30-159mm for sizing mills.

- Various composite cemented carbide roll rings for hot rolling ribbed steel bar and rods.

- Services are provided such as composite rolls design, groove machining and thread processing.

Various compatible tools can be provided for machining composite cemented carbide roll rings.

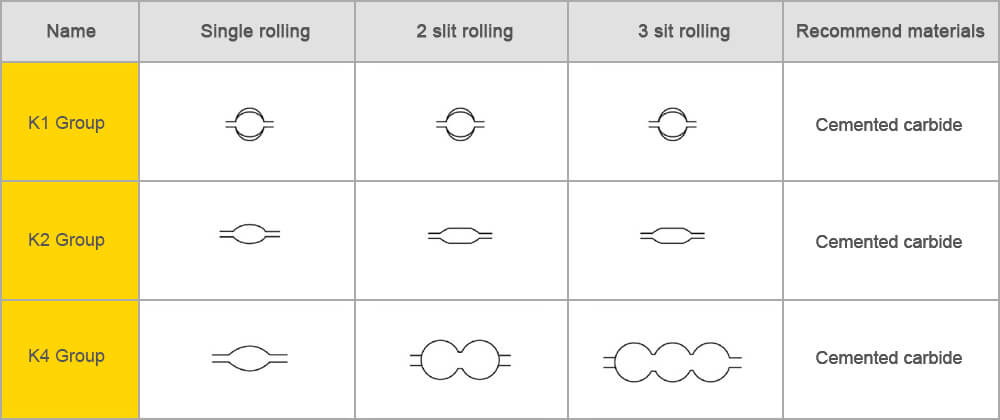

We can design and manufacture single-line rolling, two-slit rolling, three-slit rolling and combined hard alloy rolls according to customer production line and rolling process. The products include wire, bar and rebar.

The high output of the cemented carbide composite roll can effectively reduce the times of roll changes and incress the unit output. The products are produced have the characteristics of good quality on the surface, small deformation, high negative tolerance rate and finished product rate.

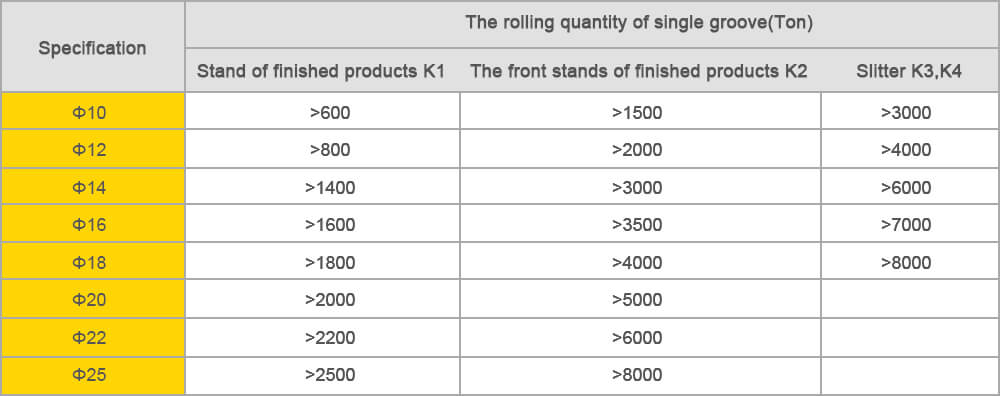

The rolling quantily of composite cemented carbide rolls

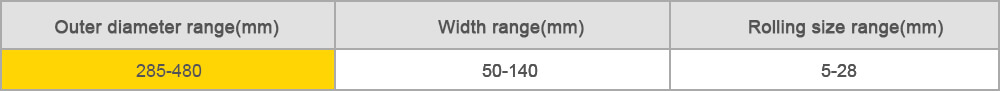

Cemented carbide composite rolls specifications

Rolling process for hot rolling rods and rebar