PRODUCTS

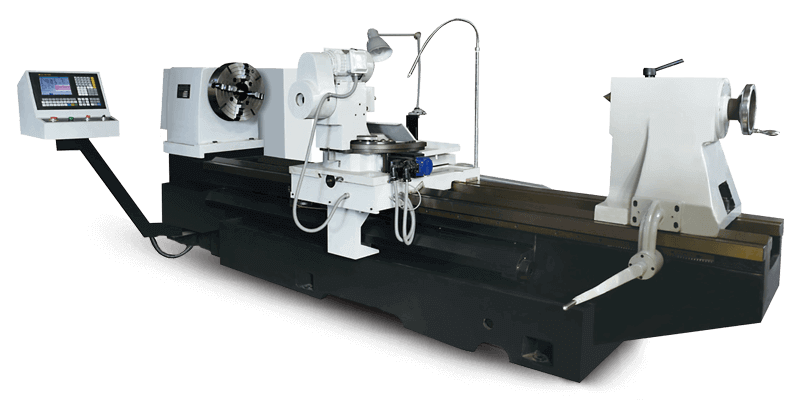

XK9350A CNC Roller Crescent Grooves Miller

In the size range of 6–50mm, reinforced concrete hot-rolled with rib rein-forced steel roll crescent slot, such as high rib groove processing applies to XK9350 series CNC roll milling machine for the crescent. With a high degree of automation, high processing precision, high cutting efficiency machine is easy to operate, safe and reliable, low labor intensity. Especially XK9350ZF-1 is more suitable for the processing of Tungsten carbide roll rings, High speed steel and the composite roll. It can be milled grooves, engraving machine and so on characteristics.

- It is ideal name writing machine. A piece of marking toll is able to do marking about 100 passes.The cost for one pass marking is only about US$1.00.

- All English letters from A to Z and all numbers from 0-9 have been stored in CNC programs. You can pick up any English letter and number for name writing by your self.

- Besides that this machine is able to do crescent notching.

- Germany SIEMENS controller c/w ’step motor’. Beat all China made PC base controller.

- Fast notching and logo marking.

- Automatic lubricant pump give guide way lubricant automatically. Avoiding lack of lubrication by one-shot manual lubricant pump.

- Available for Ni-Cr casting iron roll, S.G roll, Admite roll and H.S.steel roll.

| Item | XK9350A |

| Max.Diameter of roller | φ100—-φ500mm |

| Max.Length of roller | 2500mm |

| Suitable for threaded steel sizes | φ6—φ50mm |

| Cutting and milling method | Milling heard swivel cutting |

| Rotation of main milling head shaft | 30–3000rpm/2.2KW |

| Min.feed unit | 0.001mm(AC servo drive) |

| Conical hole for main heard frame shaft | MT5 |

| Chuck of main head frame shaft | Φ400mm |

| CNC system | According to clients’ requirements |

| Power of main motor | 380V/50HZ |

| Dimension(L×W×H) | 4000×1580×1900 |

| Machine weight | 4700kg |

| Remarks | Normal Material Rolls |