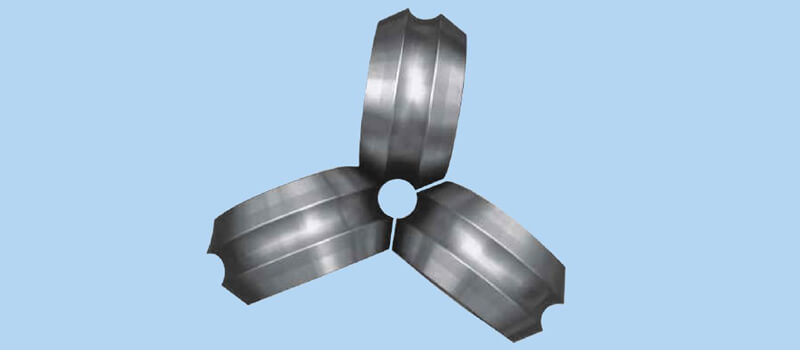

Cemented carbide roll rings for hot rolling of seamless steel tubes

The lifetime of cemented carbide roll rings is 50-80 times that of conventional roll rings when they are used at tension tube, and the surface quality and dimensional precision is substantially improved. Based on the conditions of tension tube reducing machines(Rolling force, speed, tube diameter) what is recommended is the use of either integrated roll rings or composite roll rings, achieving a good performance-price ratio.

Optional cemented carbide grades: B253 B303 For properties see the table above.

- A small clearance fit or transition fit is recommended for roll rings and roll shafts to avoid slipping between roll rings and roll shafts.

- During assembling the preheating temperature for roll rings shall not exceed 300℃.

Otherwise it will reduce the performances of roll rings.

- Water nozzles shall be installed in a proper position and run smoothly.

- As the operating lifetime of roll rings is very long, on-time inspection of the stands should be done and lubricant oil should be replenished after each rolling operation.

- A correcct colling can reduce the wear of roll rings and increase the lifetime of roll rings, cutting down the times of roll changes and keeping the surface quality of rolled material in a good state as well. The water pressure required is 0.2-0.4Mpa and the water flow rate is 20-40m3/hr.